GUEST COLUMN:

Jacqui Murray

Director for South Wales

High Value Manufacturing Catapult

We talk about productivity in manufacturing as though it begins and ends with efficiency metrics, automation, and lean systems. But the truth is that no amount of process engineering can compensate for a disengaged workforce.

Productivity isn’t simply about the machines we buy or the data we capture. It’s about how we connect and empower the people behind them.

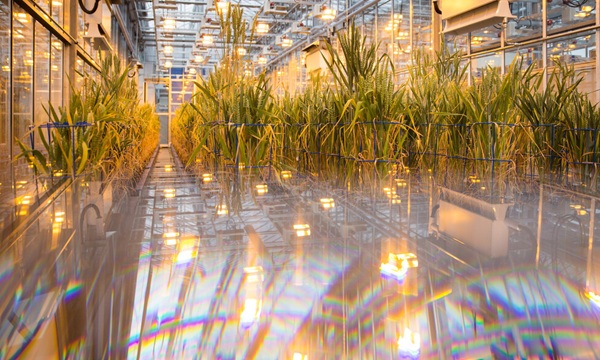

That belief underpins much of my career and everything we’re building at the High Value Manufacturing Catapult in Wales. Our digital factory hub in Baglan demonstrates the latest technologies, from digital twins to sustainable manufacturing systems, but its real purpose goes beyond the kit on display. It’s about equipping manufacturers with the confidence and culture to adopt change, and that starts with people.

When I began my career in the steelworks at Llanwern and Port Talbot, I saw how teams could roll record shifts when they trusted each other and took pride in what they were achieving together. As the only woman for sometimes miles, I also felt safe in those teams, and it was fun. Those experiences shaped my view that transformational change can only happen when the shop floor is engaged. If your team is motivated, there’s almost nothing you can’t do.

Yet as engineers, we are often trained to focus on process over people. We pride ourselves on finding the right technical answer – the data-driven, lean, continuous-improvement solution. But hearts and minds are fundamental to real, sustained transformation. Without them, even the smartest strategy falters.

Throughout my time leading the Faraday Battery Challenge, which helped establish the UK’s first gigafactories and attracted billions in investment, I saw the same truth play out. The success of that programme wasn’t just in the technology or the funding; it was in how we built a movement that connected people with a shared purpose. Whether you’re changing a small process on the factory floor or reimagining a national industrial strategy, progress depends on the strength of those human connections.

We talk a lot about collaboration these days – it has almost become a cliché. But genuine collaboration is messy. It’s not about everyone agreeing; it’s about bringing different views to the table and learning to work through the tension that follows. That’s how innovation happens. Yet very few engineers receive formal training in managing conflict, listening, or resolving disagreement. We train for every technical skill except the one that allows us to work effectively together.

In my years at the Environment Agency, I learned more about people than any engineering textbook could teach – sometimes through difficult conversations with farmers or steelworkers who were angry or frustrated. That experience taught me the value of communication, empathy, and resilience. These are not soft skills; they’re the foundations of high performance.

There’s also a growing need to rediscover curiosity. Despite having more data and computing power at our fingertips than ever before, we’ve become less open to learning from what we don’t know. Leaders can feel pressure to appear certain and in control, but the best leadership often means admitting what you don’t know and trusting your team to help find the answers. That trust is what allows creativity to thrive.

The best teams I’ve worked with, whether in steelmaking, regulation, or innovation, shared that sense of collective problem-solving. There’s a particular joy in “fixing stuff together”. It’s not a phrase you’ll find in management literature, but it captures something vital about manufacturing culture. The most effective teams don’t just have technical expertise; they have the emotional safety to challenge, question, and create together.

That’s why I’m now developing training content for manufacturing leaders focused on people skills – managing conflict, emotional resilience, and creating psychologically safe environments. When leaders learn how to engage their teams, the gains can be vast. A disengaged workforce can quietly hold back a factory for years; an engaged one can transform it almost overnight.

For anyone leading a business that feels “flat out but still not where you want to be”, it’s worth pausing to reflect. If your teams are firefighting constantly, with no time to innovate or think creatively, the issue may not be capacity or capital – it may be culture. And culture is something that can be changed.

Some of the world’s most innovative companies, like 3M, give their people 15% of their time to be creative and explore new ideas. That time to think isn’t a luxury; it’s a productivity strategy. If we want Wales’ manufacturing sector to thrive, to become greener, more advanced and more resilient, we must start by creating workplaces where curiosity, creativity, and collaboration are built into the fabric of how we work.

Jacqui Murray talks about this and more in the Productivity Reimagined podcast. Listen here.